Application of Non-Destructive Testing and Signal Processing Characteristics to Identify Defects and Microstructural Changes in Advanced High Strength Steels by Isaac Garcia C in Trends in Civil Engineering and its Architecture in Lupine Publishers

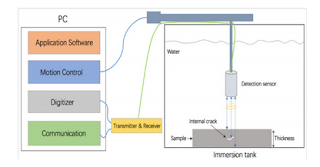

Nondestructive testing (NDT) and signal processing were used to detect, locate and define surface and internal defects in unidirectionally solidified laboratory ingots. These defects included cracks, voids, coarse non-metallic inclusions and heavy chemical and microstructural segregation. Many NDT techniques have been developed and used to assess the presence of these defects. The factors responsible for these defects are often related to mechanical, thermal, or transformation stresses during the solidification process of continuously cast steels. The high thermal stresses result from the difference expansion or contraction behavior caused by the frequency of the temperature fluctuation during solidification. In order to study the effect of these temperature fluctuations to the defects, a specially designed copper chill mold that simulates the solidification rate of continuously cast slabs was designed. In addition, a NDT-UT system was applied to localize and describe the presence of defects caused by thermal or transformation stresses. Furthermore, the signal processing analysis was used to characterize the changes in microstructure and hardness. The results of those studies are presented and discussed.

https://lupinepublishers.com/civil-engineering-journal/fulltext/application-of-non-destructive-testing-and-signal-processing-characteristics-to-identify-defects-and-microstructural-changes-in-advanced-high-strength-steels.ID.000143.php

For more Lupine Publishers Open Access Journals Please visit our website: https://www.lupinepublishers.us/

For more Journal of Civil Engineering Research articles Please Click Here: https://lupinepublishers.com/civil-engineering-journal/

Nondestructive testing (NDT) and signal processing were used to detect, locate and define surface and internal defects in unidirectionally solidified laboratory ingots. These defects included cracks, voids, coarse non-metallic inclusions and heavy chemical and microstructural segregation. Many NDT techniques have been developed and used to assess the presence of these defects. The factors responsible for these defects are often related to mechanical, thermal, or transformation stresses during the solidification process of continuously cast steels. The high thermal stresses result from the difference expansion or contraction behavior caused by the frequency of the temperature fluctuation during solidification. In order to study the effect of these temperature fluctuations to the defects, a specially designed copper chill mold that simulates the solidification rate of continuously cast slabs was designed. In addition, a NDT-UT system was applied to localize and describe the presence of defects caused by thermal or transformation stresses. Furthermore, the signal processing analysis was used to characterize the changes in microstructure and hardness. The results of those studies are presented and discussed.

https://lupinepublishers.com/civil-engineering-journal/fulltext/application-of-non-destructive-testing-and-signal-processing-characteristics-to-identify-defects-and-microstructural-changes-in-advanced-high-strength-steels.ID.000143.php

For more Lupine Publishers Open Access Journals Please visit our website: https://www.lupinepublishers.us/

For more Journal of Civil Engineering Research articles Please Click Here: https://lupinepublishers.com/civil-engineering-journal/